President Xi Jinping has called on Chongqing to bear in mind the principle that cities should be built by the people and for the people, and to actively explore new ways for the modernization of governance in super-large cities.

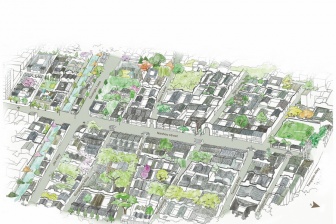

Bringing the history back to the homes

Bringing the history back to the homes

Industry forum sheds light on AI's role in filmmaking

Industry forum sheds light on AI's role in filmmaking

Chongren ancient town preserves rich heritage

Chongren ancient town preserves rich heritage

京公网安备 11010502032503号

京公网安备 11010502032503号